Description

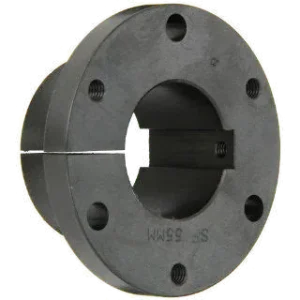

Definition: B Bushing with a 1-3/16″ Bore

The B Bushing with a 1-3/16″ bore serves as a dependable plain bearing in machinery, accurately locating and supporting rotating shafts while keeping friction to a minimum. Its design ensures precise alignment and strong radial stiffness, delivering smooth, efficient performance even under heavy loads—perfect for applications where reliability is non-negotiable.

In industrial environments, this bushing often steps in as a smarter alternative to traditional metal bearings, especially when wear resistance and corrosion protection are top priorities. Lighter than metal, plastic bushings and plastic sleeve bushings also offer superior chemical resistance, which can translate to longer life and lower maintenance costs in the right conditions.

Crafted from high-performance engineering plastics, the B Bushing handles steady loads with minimal need for lubrication. Whether it’s powering agricultural equipment, smoothing out automotive assemblies, or keeping production lines running, it provides quiet, consistent operation under tough demands—helping extend equipment life and reduce downtime.

What Are the Main Uses of a Type B Bushing?

Type B bushings pop up in all sorts of places, but they’re mostly there to act as bearings—sitting between moving parts and the frame to cut down on friction and keep everything running smoothly. With their spot-on fit, they hold shafts steady, reduce wear, and help save energy along the way.

On top of that, these bushings shine when you need to dampen shocks or soak up vibrations, especially in cars, heavy machinery, and industrial gear. They take the edge off harsh jolts, protect the equipment, and make things run quieter and more reliably. That’s why you’ll find them playing a key role in tough, high-demand setups.

How to Choose the Right B Bushing?

When choosing the right B Bushing, the first factor to consider is the bore size, which should match the diameter of the shaft. Ensuring a proper fit is crucial for stable operation and minimal friction. If the bore is too small or too large, it could lead to increased wear or improper alignment.

Next, the material of the bushing plays a vital role. Different materials are suited for different environments. For applications with heavy loads, metal bushings such as copper or steel are ideal. However, if the environment requires high corrosion resistance or lighter weight, a plastic bushing or plastic sleeve bushing would be a better choice. These plastic bushings offer excellent chemical resistance and a longer service life.

Another important consideration is the load capacity. Different applications require different load-bearing capabilities. For instance, heavy machinery or high-speed equipment demands bushings with higher load capacities to prevent excessive wear or failure. Ensuring that the bushing can handle the expected loads is crucial to prevent damage to the equipment.

Lastly, temperature and environmental conditions should be taken into account. In high-temperature, humid, or corrosive environments, it may be necessary to choose a bushing that is resistant to heat or corrosion. This ensures that the bushing will maintain its performance even under harsh conditions.

Is the Installation and Maintenance of a B Bushing Difficult?

Installing a B Bushing is generally a straightforward process. First, ensure that the bore and shaft contact surfaces are clean and free of debris to avoid unnecessary wear during installation. Then, gently place the bushing into the shaft bore, making sure it is properly aligned. Finally, press it into place gradually until it is fully seated. These steps are simple to follow and typically do not require specialized tools.

When it comes to maintenance, B Bushings are also easy to manage. Regularly checking the bushing for signs of wear is important, especially in high-load or high-speed applications where the bushing may experience more stress. Periodically adding lubricant can help reduce friction and extend the bushing’s lifespan. In environments with more demanding conditions, such as high humidity or exposure to chemicals, plastic bushing or plastic sleeve bushing may require more frequent inspection and maintenance.

In addition to B Bushings, our company also offers a range of high-quality related accessories to meet the needs of various industrial applications. These accessories include, but are not limited to:

- Bearings: Used to support rotating shafts, reduce friction, and improve machine efficiency. We offer various types of bearings, including ball bearings and sliding bearings, suitable for different load capacities and working conditions.

- Bushing Housings: These components act as the supporting structure for bushings, ensuring stable alignment between mechanical parts and extending the service life of equipment.

- Vibration Dampening Washers: Used to absorb vibrations and reduce shocks, commonly found in automotive and industrial equipment. These washers help minimize noise and vibrations during operation.

- Sliding Bushings: Similar to B Bushings, sliding bushings reduce friction and wear, and are used in equipment that requires long-term load-bearing. They are typically made from high-strength plastics or metals, offering durability and reliability.

- Plastic Bushings and Plastic Sleeve Bushings: Ideal for environments with chemical corrosion, these bushings offer excellent resistance to corrosion and are lightweight. They provide a durable and wear-resistant solution for various industrial applications.

Our company not only supplies these accessories but also offers custom-sized and material-specific products to ensure optimal performance in different working conditions. Whether in high-temperature, high-pressure, or corrosive environments, we provide tailored solutions to help customers optimize equipment performance and enhance productivity.

FAQ

How can I tell if my equipment needs a B Bushing replacement?

If you notice excessive wear, unusual noise, or unstable operation, it could be a sign that the bushing is damaged. Regular inspection, especially in high-load and high-speed environments, can help detect issues early and prevent further damage to the equipment.

What industries and equipment are B Bushings suitable for?

B Bushings are commonly used in industries like agriculture, automotive, and industrial machinery, particularly in equipment that requires high load-bearing and reduced friction, such as tractors, harvesters, and fans.

How can I extend the lifespan of my B Bushing?

Regularly clean the surface of the bushing to prevent debris buildup and maintain proper lubrication to reduce friction. Periodically check for signs of wear and replace any bushings that show excessive damage to ensure continued smooth operation.

Can I install a B Bushing myself?

Installing a B Bushing is relatively straightforward. Ensure the bushing matches the shaft’s bore size and avoid applying excessive force during installation to prevent damage. Proper cleaning and lubrication can also help ensure a smooth installation process.