Description

Product Parameters

Product Overview

M QD Type Bushings (quick-detach taper bushings) function as a widely adopted removable taper-lock connector in mechanical power transmission assemblies. They integrate with belt pulleys, sprockets, timing pulleys, or gears to couple shafts to hubs rapidly while preserving precise alignment. As standard catalog components, these bushings simplify mounting and disassembly, thereby reducing downtime during routine maintenance.

The M-series QD bushing operates via a taper-lock mechanism, delivering precise concentricity and robust torque transmission, enabling reliable performance in heavy‑duty, maintenance‑intensive applications such as conveyors, blowers, and pumps. Replacing conventional bushings with the M-series can meaningfully reduce downtime by shortening maintenance windows and mitigating misalignment under fluctuating loads.

Under appropriate operating conditions, these materials can substitute for plastic bushings, particularly in configurations employing stainless steel or high-strength alloy parts. Relative to plastic bushings, they exhibit superior wear resistance and enhanced corrosion protection, which, in turn, contribute to an extended service life of the overall assembly.

M QD Type Bushings Installation Guide

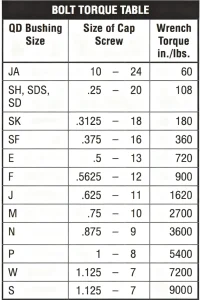

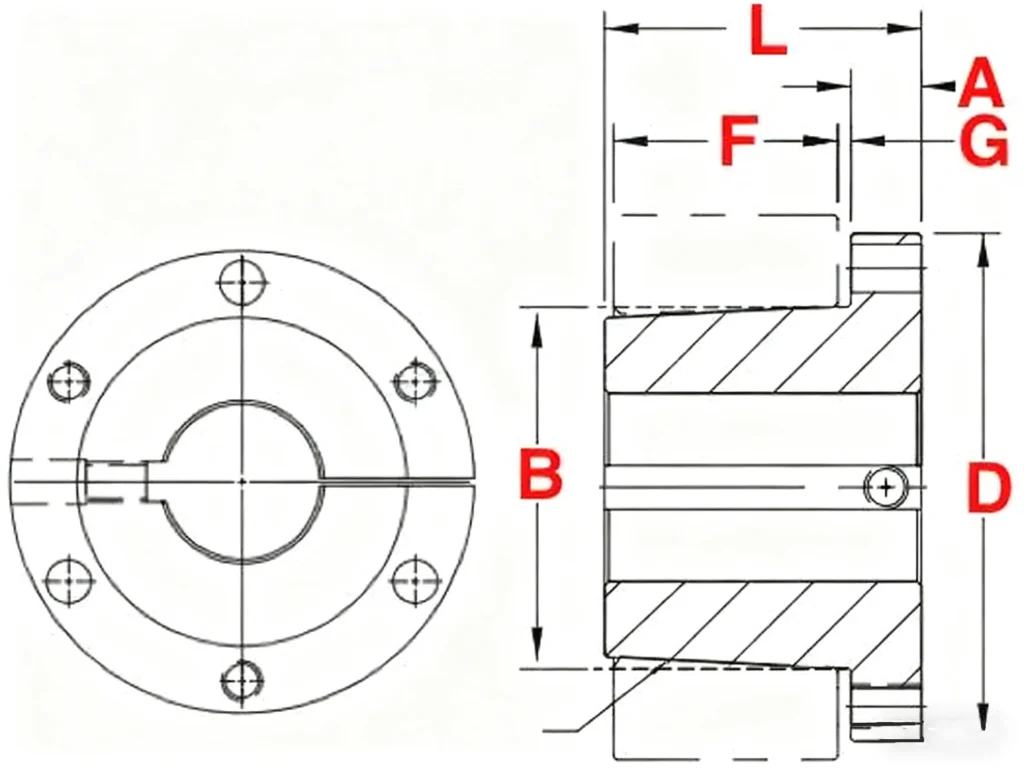

The installation can be completed under standard conditions. Insert the bushing into the hub bore, align the keyway, and tighten the flange bolts in a crisscross pattern with a torque wrench, adhering to the maker’s spec for best engagement; typically finished in a few minutes.

Disassembly is facilitated by relocating the bolts to the jacking holes and tightening them in the prescribed sequence, causing the bushing to loosen without harming the hub or shaft. The hub and shaft remain undamaged.

This quick-on, quick-off design substantially reduces installation time and eliminates the surface damage associated with old-school keyways or shrink fits, thereby lowering long-term upkeep costs.

QD Bushings vs. Other Quick-Release Types

QD bushings (Quick Detachable Bushings) are considered veterans in the field of mechanical transmissions, but there are many other quick-release counterparts on the market, such as Taper Lock, Keyless Bushing, and Split Taper. Below, we’ll discuss the differences between these three and QD bushings to help you choose the right one.

| Feature | QD Bushing | Taper Lock | Keyless Bushing | Split Taper |

|---|---|---|---|---|

| Design | Tapered sleeve + flanged hub + split inner ring, bolt-pull clamping | Half-moon taper sleeve + direct bolt pressure on hub | Inner/outer taper rings + hydraulic or bolt compression | Double taper + external clamp bolts |

| Mounting Speed | ★★★★★ Drop in, align keyway, cross-tighten bolts—done in 3-5 min |

★★★★ Fit half sleeve first, then tighten—bit more fiddly |

★★ Needs special tools or hydraulic pump—takes time |

★★★ Align split seam, extra steps |

| Removal Ease | ★★★★★ Shift bolts to jacking holes—pops right out |

★★★ May need tapping, can nick shaft |

★ Hydraulic release or special wrench—slow going |

★★★★ Loosen bolts, pry apart |

| Torque Rating | High (M size up to ~100 kNm) | Medium-high | Highest (200+ kNm possible) | Medium-high |

| Concentricity | Excellent (self-centering taper) | Good | Outstanding | Good (watch split seam) |

| Shaft Size Range | Broad (12–200 mm common) | Broad | Larger diameters | Medium range |

| Shaft Damage | Virtually none | Light pressure marks | Zero | Light |

| Cost | Mid-range | Low | High (hydraulic even pricier) | Low-mid |

| Typical Use | Conveyors, fans, pumps, general power transmission | Light-duty pulleys, farm equipment | Heavy mills, wind turbines, marine | Mid-duty sprockets, compressors |

M QD Type Bushings Benefits

Compared to plain straight bore or flanged bushings, the M QD quick-detach taper bushing really shines in day-to-day use. Here’s what sets it apart:Fast mounting and removal: Slide it in, tighten a few bolts, and you’re locked in place. Pull it off by jacking the same bolts in the release holes—no re-alignment needed, even after dozens of swaps.

Dead-on concentricity: The taper self-centers every time, keeping pulleys running smooth with less vibration. That means longer life for bearings, seals, and the whole drivetrain.

Gentle on shafts: Clamping force spreads evenly around the circumference—no keyway gouging or stress risers. Your shaft stays clean and unscratched for years.

Field-friendly maintenance: Just a torque wrench and you’re good—no special pullers, presses, or heat required. Any tech on site can handle a swap in minutes.

Fits right in: Works with most standard belt pulleys, sprockets, and timing pulleys off the shelf. Keeps inventory simple and changeovers painless.Some shops used to run plastic bushings for corrosion resistance, but heat or heavy loads would warp them fast. Switching to M QD bushings doubled service life and cut unplanned stops way down. Bottom line: less downtime, lower spare parts spend, and your line keeps rolling.

Typical Applications of M QD Type Bushings

M QD type quick-release bushings are useful in many applications, including:

Conveying Equipment: Various belt conveyors, bucket elevators, screw feeders—quick replacement during downtime allows for rapid production line recovery.

Power Transmission: Pulleys for fans and pumps, sprockets at the output end of reducers, synchronous belt pulleys, or coupling seats for gearboxes—particularly suitable for applications requiring high torque and concentricity.

Agricultural Machinery: Harvester roller drives, seed metering shafts for seeders, PTO outputs for tractors—in dusty environments with frequent disassembly and cleaning, QD bushings reduce the need for carrying numerous tools.

Mining and Heavy Duty: Eccentric shafts for jaw crushers, feed ends for ball mills, drive wheels for underground scraper conveyors—in harsh environments with high load impacts, the durability and quick-release of QD bushings save significant maintenance time.

Some mines previously tried using plastic bushings for rust prevention in damp areas, but they wore down quickly. After switching to QD (Quick Drilling) bushings, inspections are only required every six months, and the workers say it’s much more convenient.

When selecting a model, just consider three things: shaft diameter, required torque, and whether the site is dry, wet, or corrosive. Following the sample list to choose the right model is generally a safe bet.