Plastic Bushings

As a leading manufacturer, supplier, and exporter of bushings, we offer high-quality bushings and other products such as agricultural gearboxes, reducers, motors, chains, sprockets, gears, shafts, pulleys, couplings, and more—all of which are of reliable quality.

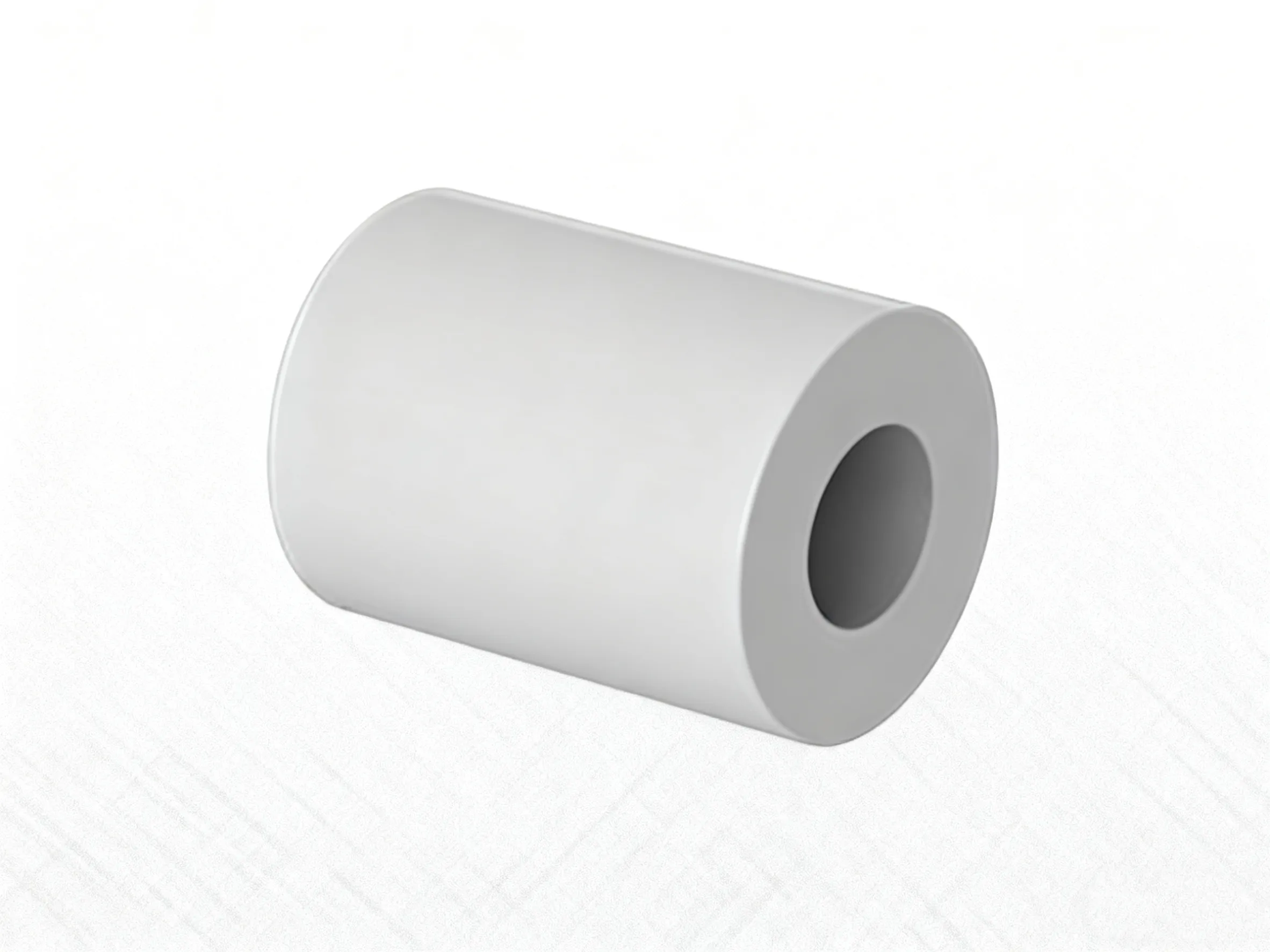

What are plastic bushings?

A plastic bushing is a component used in mechanical transmission and motion systems. Its primary function is to provide support and guidance between the shaft and the housing or bearing seat, while reducing friction and wear during operation.

It serves as a lightweight, maintenance-free alternative to traditional metal or bronze bushings, offering smooth performance and extended service life in a wide range of applications.

Material Options

Our plastic bushings are made from high-performance engineering plastics such as Nylon (PA), POM, PTFE, and UHMWPE. Different materials are available to balance strength, wear resistance, and cost for various applications.

Temperature Resistance

Standard materials operate between -40°C and 100°C, while PTFE bushings can withstand continuous use above 200°C, suitable for most industrial and agricultural environments.

Wear Resistance

Plastic bushings feature excellent self-lubricating and low-friction properties, providing better wear resistance than many metal bushings in low- to medium-speed or dry-running applications.

Lubrication Requirement

Most models are maintenance-free and require no additional lubrication. A small amount of grease may be used under heavy load or high-speed conditions to extend service life.

Corrosion Resistance

These bushings offer outstanding anti-rust and chemical resistance, making them ideal for humid, acidic, or salt-laden environments where metal parts would corrode.

Deformation & Aging

Reinforced materials ensure dimensional stability under normal use. For high-temperature or outdoor applications, UV- and heat-resistant grades are available to maintain performance over time.

What Materials Are Used for the Bushings?

Our plastic bushings are made from high-performance engineering plastics, including nylon (PA6/PA66), polyoxymethylene (POM), polytetrafluoroethylene (PTFE), and ultra-high molecular weight polyethylene (UHMWPE).

Each material brings its own strengths: nylon offers excellent wear resistance and toughness; POM delivers great rigidity and dimensional stability for tight fits; PTFE excels in self-lubrication and chemical resistance; and UHMWPE shines in low-speed, heavy-load scenarios with outstanding durability. Pick the one that fits your setup, and we can even tweak the formula—adding glass fiber or carbon fillers, for instance—to boost strength or heat tolerance as needed.

Projects

Satisfied Clients

Ongoing Projects

Years of experience

Application of Plastic Bushings

Plastic bushings are widely used across a variety of mechanical and industrial systems due to their combination of light weight, wear resistance, and self-lubricating properties. They are often chosen as a practical alternative to metal bearings in environments where traditional lubrication is inconvenient or where corrosion resistance is essential.

In agricultural machinery, such as sprayers, planters, and harvesters, plastic bushings provide reliable performance even under constant vibration and exposure to moisture or fertilizer chemicals. Their non-corrosive nature allows the equipment to operate smoothly without frequent maintenance or replacement.

In conveyor and automation systems, the low-friction performance of plastic bushings helps ensure stable motion while minimizing noise and energy loss. They are ideal for continuous operation in packaging lines, food processing machines, and assembly systems where cleanliness and smooth motion are priorities.

For industrial equipment like pumps, mixers, and ventilators, plastic bushings can replace traditional Shaft Bushings to reduce weight and eliminate the risk of rust. They also perform well in humid, dusty, or chemically active environments, maintaining consistent alignment and reducing machine downtime.

Overall, plastic bushings offer an effective balance between durability, cost-efficiency, and ease of use, making them suitable for applications that demand quiet operation, low maintenance, and long-term reliability.

Bushings for Sale

We are a bushing manufacturer, dedicated to serving you. The following is only a partial list of our products; our factory offers a full range of bushings. If you require customized products, please feel free to contact us, and we will reply within 24 hours!

Articles about burning

Key Features of Bushings

Compared with traditional metal parts, plastic bushings provide lightweight, durable, and maintenance-free performance. Their self-lubricating materials ensure smooth, quiet motion without the need for additional grease, making them ideal for clean or hard-to-maintain environments.

They also offer excellent corrosion resistance—unlike metal, they won’t rust or seize even in humid or chemical conditions. Easy to install and up to one-tenth the weight of steel, plastic bushings reduce overall machine load while minimizing noise and vibration.

In short, they deliver reliable, long-lasting performance and help lower maintenance costs in modern mechanical systems.

How to Choose Plastic Bushings

When picking plastic bushings, start by looking at the operating conditions. In wet or chemically aggressive environments, go with PTFE or UHMWPE—they resist corrosion and aging, staying reliable without rusting or seizing over time. For higher temperatures, modified nylon or glass-fiber-reinforced versions hold their shape and provide solid support under heat.

Load and duty cycle matter too. For equipment that runs hard with frequent shocks, choose tougher, more wear-resistant grades. If it’s light-duty or intermittent use, standard nylon or POM will do the job just fine. Don’t overlook fit—match the bore to your shaft tolerance for smooth installation and longer service life.

Maintenance is another plus: most plastic bushings run dry with no lubrication needed, cutting down on upkeep. If you’re swapping parts often, Flanged Bushings make alignment easy and replacement quick. Bottom line: match the material to the environment, size it right, and install it cleanly—you’ll get dependable performance every time.

From Our Clients

The following are user reviews of us.

“We’ve been sourcing plastic bushings from this supplier for over a year. The dimensional accuracy and surface finish are consistent, and the parts fit perfectly with our existing equipment. Delivery is always on schedule — very dependable partner.”

“The technical support team was quick and precise. They helped us choose the right Shaft Bushings for our pump project, and the performance has been flawless ever since. Excellent communication and attention to detail.”

“We replaced several metal bushings in our assembly line with Flanged Bushings, and the results were impressive. Lower noise, easier installation, and zero maintenance so far. It’s the kind of small upgrade that makes a big difference.”

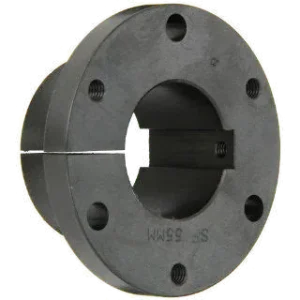

“We ordered a custom batch of QD Bushings, and the machining quality exceeded expectations. Everything was well packaged, and the documentation made installation easy. It’s refreshing to work with a supplier who understands what engineers actually need.”